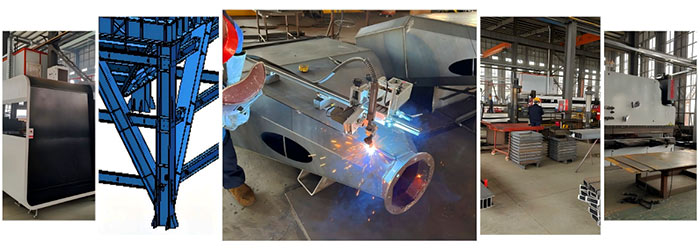

CAFU Machinery delivers precision-engineered heavy steel fabrication services that combine advanced technology with 15 years of expertise, empowering industries to build robust, long - lasting infrastructure. From mining conveyors to building materials machinery frameworks, our custom heavy structure fabrication solutions offer users diverse and cost - effective options.

1. The CAFU Heavy Steel Fabrication Process

A. Design & Engineering

Our process commences with the collaboration between structural engineers and users to optimize load distribution and material usage. Custom fabrication blueprints adhere to the users' design standards, ensuring structural integrity under extreme conditions.

B. Cutting & Forming

• Laser/Plasma Cutting: Capable of achieving precise cutting of steel materials below 120mm thickness.

• Press Brake Forming: 1200-ton CNC machines create complex geometries (length can reach up to 12 meters).

• Roll Bending: Steel plates with a thickness of 35mm or less can be easily formed.

C. Welding & Assembly

• Robotic Welding: Welding for 100% penetration on critical joints.

• Manual TIG/MIG: Skilled welders handle intricate connections in confined spaces.

2. Core Services Overview

|

Service |

Capabilities |

Industry Applications |

|

Custom Metal Fabrication |

- Mining chutes - Crusher bases |

Mining, Cement, Power Plants |

|

Structural Steel Fabrication |

- Beams/columns - Truss systems |

Construction Machinery, Heavy Machinery |

|

Heavy Fabrication |

- Cement silo - Conveyor frames |

Cement, Material Handling |

|

Rolling & Forming |

- Cylinders - Curved supports |

Key Manufacturing Processes |

|

Painting & Blasting |

- SA 2.5 surface prep - Epoxy-Zn coatings |

Key Manufacturing Processes |

3. Quality Assurance: The CAFU Difference

• Weld Inspection: We commission SGS-certified welding inspectors to validate critical welds using ultrasonic testing (UT) and dye penetrant methods.

• Material Traceability: The raw materials are sent to testing machinery for inspection to ensure the alloy composition.

• In-plant Pre-assembly: With the cooperation of large overhead bridge cranes in the factory, pre-assembly is carried out in accordance with the requirements of the installation drawings to ensure the smooth progress of project installation.

• Rigorous Packaging Protection: Compression-resistant and collision-proof packaging materials are used to package structural components to prevent component damage during transportation.

4. End-to-End Project Management

CAFU eliminates subcontracting risks through integrated services:

• Design: Project engineers collaborate with clients on a one - to - one basis.

• Fabrication: A well - equipped manufacturing plant that can meet various heavy steel fabrication requirements.

• Finishing:

1. Shot blasting

2. Industrial epoxy coatings (120 - 250μm DFT)

• Logistics: ISO containers and special - purpose containers for oversized components.

Why Partner with CAFU?

✅ Material Options: Carbon steel, stainless (304/316), wear - resistant alloys.

✅ Large - scale manufacturing facilities and strong production capabilities ensure that products are manufactured strictly according to customer requirements and delivered on time to the port specified by the user.

✅ Lower Total Cost of Ownership: With the rare full - process heavy steel fabrication service capabilities, from the CNC metal cutting workshop to the professional hot - dip galvanizing workshop and the dedicated finished product storage yard, the manufacturing cost can be minimized.

Contact CAFU Machinery Now to Explore Our Heavy Steel Fabrication Solutions.