Through double station design, automatic marking and accurate positioning, the twin head auto scalding machine significantly improves the efficiency and accuracy of heat transfer printing, and is widely used in clothing, shoes, leather, bags and other scenes requiring large-scale ironing process. The core value is reflected in the three dimensions of efficiency, precision and safety, and the specific applications are as follows

I. Large scale hot stamping in clothing:

- Label transfer for pieces fabric: Twin head design (such as SOMAX SM-12), the left station unloads the material while the right station presses, which nearly doubles the efficiency. It is suitable for hot stamping of washing labels and size labels on T-shirts and sweatshirts.

- High-end customization: With double-heads heating, it supports multiple temperature and pressure parameter adjustments, it can process cotton, polyester, and blended fabrics, meeting the needs of fast fashion brands for small orders and quick response, and reducing changeover time.

- Safety protection: The new anti-scalding device prevents manual contact with high-temperature scalding heads, reduces the accident rate in the workshop, and is especially suitable for novice operators.

II. Precise positioning of shoe manufacture

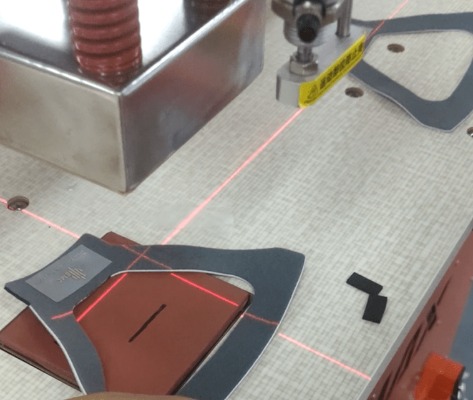

Tongue/lining label: For the irregular curved surfaces of sports shoes and leather shoes (such as the curve of tongue), the double-head machine uses positioning and laser alignment ( ±0.1mm accuracy of SOMAX SM-12 device) to solve the problem of manual labeling skewness and improve brand identity consistency.

Special technology: support hot stamping of metal labels such as gold and silver, and independent temperature control of double iron heads (for example the upper and lower independent temperature control technology of SOMAX SM-12), meeting the high-end texture requirements of brands such as AJ and Nike etc.

III. Efficient Processing of Leather Luggage

- Bag Logo Heat-Stamping: Dual workstations simultaneously process the front and back sides of tote bags and suitcases for logo stamping, reducing material handling time and storage space.

- Penetration for Thick Materials: For thick materials such as cowhide and PU leather, the pneumatic booster heating head (e.g., SOMAX SM-12) ensures that the logo is firmly stamped and does not fall off, especially suitable for the wear-resistant requirements of outdoor luggage.

IV. Core Equipment of Automatic Production Line

Two-head design for continuous operation: SOMAX twin head auto scalding machine achieves the automation of "label feeding - heat transfer - fabric collection" through the alternating pressing of the left and right heating heads, coordinated with label-feeding robotic arms and automatic lifting label feeding store. This system minimizes manual intervention and is ideal for fast-moving consumer goods (FMCG) production lines with a daily output exceeding 100,000+ units.

With the AI technology and soft heating technology updating, SOMAX twin head auto scalding machine will develop towards full automation, multi-material compatibility, and deep scene integration, become standard equipment for intelligent manufacturing of shoes, clothing and leather.